Bicycle Glossary A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

Bicycle Glossary - S

![]()

Saddle - What you call a seat if you are in the 'inner circle' of bicyclists.

Saddle clamp - The proper term for seat clamp - which see.

SAE - Acronym for Society of Automotive Engineers. In common usage, it refers to a series of standards the society publishes for mechanical components. For instance, 1/4" SAE bolts have 20 or 24 threads per inch, and are 7/16" across wrench flats. See also ACME.

Safety check - A systematic examination of a bicycle to determine that it is in safe condition. The safety check usually includes minor repairs and adjustments if needed to bring the bike to a safe condition, but generally ignores mechanical flaws which are not dangerous. For instance, a defective brake cable would be replaced, but not a defective derailleur cable.

Safety lever - An extension to a brake handlever on a downturned, racing-style handlebar. These are not as popular as they once were, because many people say they are not as safe as not having "safety levers." The most common implementations of safety levers do not work well. Often the lever can be pulled all the way to the handlebar without full braking effect. Also, the rider's center of gravity is higher when using the top of the handlebar and therefore the safety levers. Finally, the rider's hands on the handlebar are closer together making support and control more difficult in difficult situations. Synonym: Extension lever.

Safety washer - A plate which insures that the front wheel will stay attached to the bicycle, even if the axle nuts come loose. There are usually two safety plates, one on each side of the fork. They generally mount on the outside of the fork. They have a hole through which the wheel axle protrudes, and a tab or screw which keeps them positively engaged with the fork dropout.

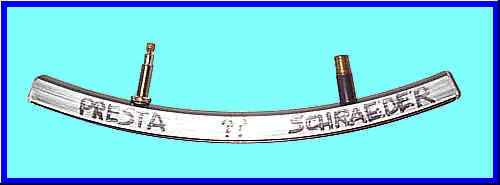

Schraeder valve - The valve found on most bicycle inner tubes, same as car tires. Also see Presta valve.

Schwinn - An American manufacturer of bicycles. Schwinn did more to introduce bicycling as a serious adult activity in the 1960's and 1970's than any other manufacturer or organization. For a long time, they made the highest quality American-made bicycles. Schwinn's attitude was oriented toward durability rather than light weight, which is evidenced by many bicycles with heavy welded steel frames, steel rims, steel cranks, steel handlebars and stems, and thick tires. For a long time, Schwinn's dimensions were different than the American Standard. This necessitated purchasing genuine Schwinn replacement parts rather than generic replacements. For instance, Schwinn tires had sizes such as 26 x 1-3/4 (inch) which seem like they would interchange with the standard 26 x 1.75, but they would not. Schwinn steering tubes and cranks used 28 threads per inch when everyone else used 24 threads per inch. This was quite maddening for inexperienced people trying to repair Schwinn bicycles or trying to use Schwinn parts on other bicycles. Some parts were interchangeable, such as pedals however. Because of Schwinn's reluctance to follow the American Standard for parts interchangeability, another standard was created, called the Schwinn Standard.

See also: Parts interchangeability chart.

Screw - A threaded rod which fits into a hole in a bicycle part. Technically, if the screw fits into a nut, then it is called a "bolt," but "screw" and "bolt" are used pretty much interchangeably. Screws generally hold two parts together, and have some sort of system to prevent loosening in a vibrating environment such as lockwashers or nylon, friction-causing inserts.

Screwdriver - A tool for turning bolts and screws. There are two common types, "straight" or "slotted" and Phillips. There are also uncommon screwdrivers such as allen head screwdrivers, and Torx, which are not used on bicycle parts. The traditional shape of a screwdriver is a round handle the size of a handgrip, with a round blade about six inches long, ending in the actual shape which fits the screw or bolt. Variations include screwdrivers with ratcheted handles, or flexible shafts, short screwdrivers, offset screwdrivers, and bits to fit in electric drills or socket sets.

Sealed bearing - A bearing which has a neoprene seal so that dirt and moisture cannot enter. There are two types of sealed bearings, standard cone-and-cup, which are regular bicycle bearings, but with seals. Cone-and-cup bearings can be overhauled and adjusted, and even though sealed, may need overhaul from time to time because seals are not perfect. The other type is cartridge bearings which are not serviceable and non-adjustable.

Seat - You can figure this one out. Sometimes serious riders call it the "saddle." Generally, the more padding a seat has, the more it weighs, and the more it squishes, which reduce the efficiency of your ride. However, for the extra comfort, many riders are willing to give up the advantages of a small, hard seat. For the occasional rider, a cushy seat is a good idea. For the more frequent rider, the smaller seat becomes comfortable with experience. In fact, because a wide seat can impede the action of the large leg muscles, the longer distance rider will almost always prefer the smaller seats.

The seat is the site of the greatest discomfort for riders new to bicycling. Most seat discomforts are overcome by simply riding very short distances at first, and working up to greater rides slowly. However, there are some warnings that you should heed. Men, especially, should be aware of numbness. Any such numbness should be fixed by ending the ride early. Try other seat positions, changing to other types of seats, a padded seat cover, or consult a health professional. Riders of both sexes can get blisters or fungus. These are minor problems if you take proper care of them right away but can become a bigger problem if you try to ignore them.

Seat clamp - The mechanism that fastens the seat to the top of the seatpost. In some cases this is a separate part, in others, it is built into the seat post. Most seat clamps allow for some adjustment of angle, although most riders prefer the seat nearly level. There is minor, decades-long controversy over the best angle. Some say that the tip of the seat should be higher than the back, because otherwise you'll waste energy positioning yourself on the seat. With the tip up, you put your weight on the back of the seat, where it tends to stay. Others say the tip should be down slightly for better health and more comfort. Probably the best bet is to experiment with seat angles, and see what you like best.

Some seat clamps allow for moving the seat forward or back a little bit. The range of adjustment is usually so small that it make little difference. Some seat clamps can be installed backward or upside-down which puts the seat farther forward or lower for small riders on large bikes.

Seat cluster - The area of a bicycle frame where the toptube, seattube, and seatstays come together.

Seating - The way a tire is mounted on a rim. It is very possible to inflate a tire that is not seated properly, and have an edge of the tire blow off the rim, which wrecks the inner tube. This is called a blowout. When inflating a tire, put just enough air in it at first to take its shape. Look at both sides all the way around, and make sure the tire is seated properly. If not, manually force it into position. Inflate the tire to full pressure in stages, examining the tire for seating problems several times during the process. If a bulge starts to appear, let the air out, and reposition the tire. Sometimes you can use soap to lubricate the tire so that it will slip into the proper position. Use soap that dries up, and remove any that gets on the sides of the rim if the bicycle has caliper brakes. Another seating problem is the opposite of bulging - flat spots, which result in a bumpy ride. A flat spot often indicates a bulge elsewhere around the tire.

Seat pillar - What people who want to sound professional call a seatpost.

Seat pin - This is what some people call the bolt that keeps the seat post from sliding down into the bicycle frame. Others call it the seat bolt.

Seatpost - the tube upon which the seat is mounted. Most seatposts are adjustable so the seat height can be just right for the rider. The proper height is such that with the arches of the feet on the pedals (we usually pedal with the balls of our feet over the axis of the pedals), the leg is just a touch less than fully extended. If you cannot achieve this position with at least two inches of seat post remaining within the bicycle

frame, get a longer seatpost. A short seatpost with less than two inches left in the bicycle frame can damage the top of the frame by bending or tearing.

Seatpost diameters vary. On most American-made bicycles, they are 13/16" in outside diameter. On some, especially

BMX bikes, they are 7/8." On most entry-level Japanese bikes and bicycles manufactured in the British Empire they are 1." On

mountain bikes with higher-quality frames, they are likely to be 26.8 millimeters, but they can vary. On higher-quality road bikes they range from 26.8 to 27.2

millimeters.

Seatstay - A tube of the bicycle frame which extends from the seat cluster (the area where the seatpost is fastened) to the rear dropout (at which the rear wheel is fastened). There are two seatstays on most bicycles.

Seattube - The tube of a bicycle frame into which the seatpost fits. The seattube extends down to the bottom bracket housing (through which the crank is mounted). On most bicycles, the seattube is 1-1/8" in outside diameter. On most American-made bicycles it is 1" in diameter. On French bicycles it is usually 28 millimeters.

Sew-Up - A thin, high-pressure tire which is tubular in nature, like a donut. Sew-ups are generally used for road racing and by tourists who want maximum efficiency and lowest weight. The tire can be inflated without being mounted on a rim because the inner tube is sewn into the tire, much like an American-style football.

Sew-ups are generally more prone to punctures and blowouts, and cost more than conventional tires, but many riders are willing to put up with these shortcomings because of the extreme light weight, and low rolling friction that sew-ups offer.

Whereas the conventional tires use air pressure and a tight fit to hold themselves onto the wheel rims, sew-ups are glued or taped on. The glue is much like contact cement. The tape is a cloth tape that is gluey on both sides. The glue or tape must dry before the tire is fully secure. Even with properly glued tires, there is a small danger of having a tire roll off the rim in a severe corner or emergency maneuver.

If a rider with sew-ups has a puncture, the rider removes the wheel, tears the tire off the glue, and puts another tire on in its place. Sew-ups make great spares, because they weigh little, and fold up very small. Many riders carry a spare behind and under the bicycle saddle. Often the rider will not reglue a spare mounted while on the road, but will depend on the old glue and careful riding on the rest of the ride to prevent the sew-up from rolling off the rim. Leaving a tire improperly glued for a long period of time is not recommended, because it can creep around the wheel due to acceleration or braking, and eventually tear its fragile Presta valve out.

There are several varieties of sew-ups ranging from durable commuting tires to very light racing tires. There are even knobby off-road sew-ups available for cyclocross competition. The lightest have very little rubber tread, and a casing made from silk cloth. The inner tubes on the lightest sew-ups are made from latex rubber which is slightly porous. The rider has to pump the tires up (to over 100 pounds per square inch) before every ride. These latex inner tubes are sensitive to oil and grease. If even one drop of lubricant gets on the side of the sew-up tire, it can soak through, and ruin the latex inner tube.

Many racers have two sets of sew-up wheels. One set is very light and reserved for racing. The other has heavier rims and tires, and is more durable. This second set is used for everyday training rides.

The rims on which sew-ups are mounted are tubular in nature also. Instead of a U cross section, they are only slightly concave on their outer surface. The spoke nipples are recessed deeper into the rim. Sew-ups are usually less than one inch (25mm) in diameter, and about 26.5 (70cm) inches in outside diameter. Sew-up wheels are interchangeable with 700c conventional wheels.

To fix a puncture, the tire is removed from the wheel. A cloth strip that is glued to the underside of the tire, which lays against the rim is peeled away from the tire for a distance of about five inches on either side of the area of the puncture. Under this cloth strip are coarse stitches, which look a bit like a laced shoe, or the stitching on a bag of kitty litter. Lateral lines about an inch apart are made with a ball-point pen across the stitches to help with alignment later on, and then the stitches are cut for a distance of about three to four inches. The puncture is located in the tube and patched just as a conventional inner tube is patched, although with the thinnest patch available.

Because the casings of sew-up tires are fragile, it is often necessary for the rider to leave a piece of cloth between the tube and tire to repair a tear in the casing.

Then the stitches are replaced with a large needle and "buttonhole and carpet" thread, available at any fabric store. The stitches are drawn fairly tight, because when the pressure is put back in the tire, they will be stretched. The lines which were drawn earlier help make sure not to cross-stitch resulting in a bit of a twist in the tire. Finally, the cloth strip which protects the stitches from rubbing on the rim is glued back into position.

Practice is required for mounting sew-up tires, especially new ones because they are a tight fit. There are several techniques for installing a sew-up tire. One of the most common is:

1. Prestretch the tire on a clean dry wheel by inserting the valve into the valve hole. Set the wheel on the ground with the valve at the top, and slide your hands down either side of the tire while leaning hard onto the wheel. As you slide your hands, you slip the tire over the edge of the rim. Until you can do this easily, do not apply glue.

2. Put glue generously all over the surface of the rim. Wait a few minutes for it to become a bit tacky. Then mount the tire as in step one, being careful not to drag glue across the braking surface of the rim.

3. Put glue generously all over the surface of the rim. Wait a few minutes for it to become a bit tacky. Then mount the tire as in step one, being careful not to drag glue across the braking surface of the rim.

5. Wait a day for the glue to dry fully before riding the bike (or use your spare wheel).

Synonym: Tubular.

Shifter - a hand-operated mechanism for changing gears. Shifters can be mounted on the handlebar, in the ends of the handlebar, on the handlebar stem, on the downtube, on the toptube, or on the brake handlevers.

See also: Derailleur.

Shimano - A Japanese manufacturer of bicycle components including hubs, shifters, derailleurs and brakes. You can visit their web site at http://bike.shimano.com.

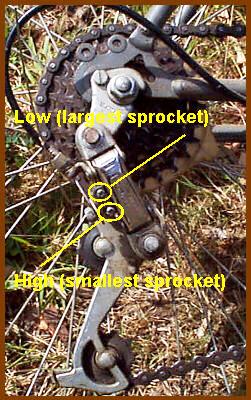

A Shimano rear derailleur

Sidepull brakes - a style of caliper brake in which the calipers pivot on a central axle. The name comes from the fact that the cable pulls the calipers together from one side.

See also: Centerpull brake, Cantilever brake.

Silver brazing - A flow brazing technique that uses brazing rods that are alloyed with typically between 20% and 40% silver. The brazing rods are expensive, but melt at a lower temperature than ordinary brass brazing rods. (1200 degrees Fahrenheit instead of 1600 degrees). The lower temperature has less effect on steel, and therefore bike frames made by silver brazing can be stronger.

Sissy bar - A U-shaped bar that holds up the back end of a banana seat. Banana seats were popular on children's bikes in the 1970s. Sissy bars generally were quite a bit higher than necessary, whereas backbars were of only sufficient height to hold up the seat. The extra height that protruded above the seat was sometimes used as a backrest, especially by passengers (not recommended).

Six-day race: Also known as Madison - which see.

Slipstreaming - Following another bicycle or other vehicle to take advantage of the vacuum created. A vehicle moving through air displaces the air momentarily. Because air is fluid, it does not return to fill in the hole created immediately. There is a low-pressure area behind a vehicle, where it is easier to ride, since the rider who is slipstreaming does not have to move as much air out of the way. This low pressure area is called the "slipstream." Slipstreamting is commonly used by racers to conserve energy. Much of the strategy in team racing is involved in figuring out who should slipstream who at various times. Synonym: Drafting.

Socket set - A set of sockets that fit nuts or bolt heads, and a bar to which the sockets can be attached. The bar is usually a ratchet, so that the socket can be turned in one direction or the other in a series of short strokes. In addition to ratchets, a socket set can include extension bars, flexible extensions, flexible couplings, breaker bars (long, solid handles), screwdriver-like handles, cranklike spinners (called speedwrenches), and air or electric tools to turn the sockets. Socket sets in America are built with square attachments between the sockets and the driving bar. The common dimensions are 1/4-inch, 3/8-inch, 1/2-inch and 3/4-inch. For bicycle repair, a 3/8-inch set is the most useful. Unless you are working on American bikes, a metric set containing sockets typically ranging from 9mm to 17mm is best.

Solvent - a liquid that mixes easily with other materials. In bicycling that generally means a liquid that can be used to wash away oil and grease, and the dirt contained in old lubrication. Do not use gasoline as a solvent because it is explosive and the fumes can be bad for your health. We recommend carefully using kerosene or non-toxic commercial solvent in a very well-ventilated, and spark-free and flame-free environment. Wear gloves.

Speedman's wobble - Some bikes will start to wobble when ridden at high speeds. The effect is especially noticeable when riding with no hands. The front wheel rhythmically oscillates back and forth. The degree of wobble can range from amusing to downright dangerous. This effect can happen with any bike, but can be enhanced by bad frame geometries, or badly adjusted or damaged (brinnelled) headsets.

Splines - A matching set of ridges and cutouts in rotating pieces that lock the pieces together rotationally, but allow easy servicing by sliding the items apart laterally.

Spokes - thin metal rods that hold wheels together.

Spoke nipple - a long thin nut that fastens a spoke to the wheel rim. By turning the nipple, the spoke can be tightened or loosened, and by adjusting several spoke nipples, the wheel can be aligned (straightened).

Spoke fatigue - A condition in which spokes start breaking at the hub. With every revolution of the wheel, the spokes bend at the hub a little bit. After thousands of miles, they work-harden, and eventually break. When one spoke breaks, the rider tends to replace it, thinking the problem is gone. However, other spokes start breaking soon thereafter, and the only reliable repair for spoke fatigue is to replace all the spokes in the wheel at one time.

Sprint - a very short race, or a short, high-speed portion of a race.

Sprocket - a toothed wheel that engages a chain. Freewheels consist of one or more sprockets. An 18-speed bike will have three sprockets on the chainwheel, and six sprockets on the freewheel. Synonym: cog. Some people will also call sprockets "gears."

Sprocket vise- a tool to remove sprockets from a freewheel. The sprocket vise is an adaptor that allows the mechanic to hold the freewheel in a vise by grabbing the sprocket. A chain type sprocket wrench is then wrapped around another sprocket to turn the freewheel. Sprocket vises are used with non-cassette freewheels only.

Sprocket wrench - a tool to remove sprockets from a freewheel. There are several forms of sprocket wrenches. Some are a bar with a length of bicycle chain attached. Others are hooks that engage one or more sprocket teeth.

Sprung fork - A fork that includes compression springs to absorb bumps so that the ride is softer, safer and more controllable.

See also: Suspension.

Stainless steel - A steel alloy containing nickel that does not rust in ordinary conditions.

See also: Chrome.

Steel - A metal. An alloy of iron and carbon, and usually small amounts of other elements. Steel is strong, but heavy in comparison to aluminum alloy. Steel also tends to rust, so steel that is exposed to weather is often chrome-plated, or alloyed with nickel, making it 'stainless.'

Steering Tube - the top portion of a fork that goes through the headtube, and to which the handlebar stem connects. Most steering tubes are threaded at the top, and the handlebar stem is inserted into the top of the steering tube. Many modern bikes use a new type of steering tube that has no threads, and the handlebar stem clamps around the top of the steering tube instead.

Stem - 1. Handlebar stem. 2. Valve stem.

Suntour - A Japanese manufacturer of bicycle components - especially brakes, hubs, freewheels, shifters and derailleurs.

A Suntour rear derailleur

Suspension - A system in which a bike's ride is made softer by compression mechanisms. The most common compression mechanism is a 'sprung' fork. Many mountain bikes also have a rear compression mechanism that includes a pivot at the front of the chainstays and a spring above and forward of the rear wheel. Suspension makes the ride more comfortable, but more important, the ride is also more controllable. If a rider without a sprung fork hits a large tree root, the bike may stop suddenly, and the rider will get a free helmet test. The downside of suspension is that some of the energy that the rider applies to make the bike go forward will be spent squishing the suspension instead. Bikes with suspension also weigh a bit more.

For more on Suspension See: Suspension

![]()

Anything missing or need greater coverage? Let me know - Jeff

Tell a Friend About BikeWebSite

Please feel free to link your web pages to www.bikewebsite.com.

Disclaimer

Although I have attempted to cover the major safety issues, I cannot be responsible for your use of this information. Working on bicycles is dangerous if you do it without considering consequences of bolts left loose, known problems which are ignored, things which should be replaced but are glued instead, and so on. Proceed carefully at your own risk and use common sense. Jeff Napier, and all agents associated with this information, do not offer any guarantee or warranty for your use of this information.